With more than 75 years of innovation behind it, Kemppi has earned a global reputation as a leader in welding technology. In Australia and New Zealand, the company continues to play a growing role in helping fabricators meet rising expectations around productivity, quality, and compliance.

In this Q&A, Mark Shaw, Managing Director of Kemppi Australia, reflects on the company’s origins and its evolution from a manufacturer of reliable welding equipment into a modern welding technology partner delivering advanced digital and automated solutions.

Shaw outlines Kemppi’s core strengths (including the high-performance X5 FastMig platform and the WeldEye welding management software), and explains how the integration of industrial-grade equipment with real-time data and traceability tools is helping fabricators improve weld consistency while reducing risk.

With sustainability, safety, and skills shortages shaping the future of fabrication, Kemppi’s focus remains clear: supporting welders and businesses with solutions that make welding safer, smarter, and easier to manage, while ensuring confidence in quality outcomes across steel and construction projects.

Kemppi has a long history in welding technology. Can you tell me about how Kemppi was founded, and what initial gap in the market it was designed to fill?

Kemppi was founded in Finland in 1949 to primarily solve a very practical problem – making welding equipment, which was heavy, inefficient and inconsistent at the time; more reliable, efficient, and easier to use and control. This focus on usability and quality has stayed with the company ever since.

Since its founding, how has Kemppi evolved in terms of its offerings, markets, and strategic focus?

Kemppi has grown from a local manufacturer into a global welding technology company, with a long-standing presence here in Australia and New Zealand. The product range has also expanded significantly over time. Today, we offer a comprehensive range of welding machines, torches and safety gear, as well as digital welding software and automated solutions. What has not changed is the focus on helping customers improve their welding quality and productivity. More recently, this has meant helping fabricators better manage and control documentation, traceability, and compliance as part of their everyday welding operations.

Kemppi is known for its advanced welding solutions. What would you describe as your core product strengths or flagship offerings today, and why are they important to customers?

At a practical level, one of our strengths is in combining solid, industrial welding equipment with digital tools that support quality and compliance. A good example of this is the X5 FastMig platform, which is designed for high-performance steel fabrication environments where consistency really matters.

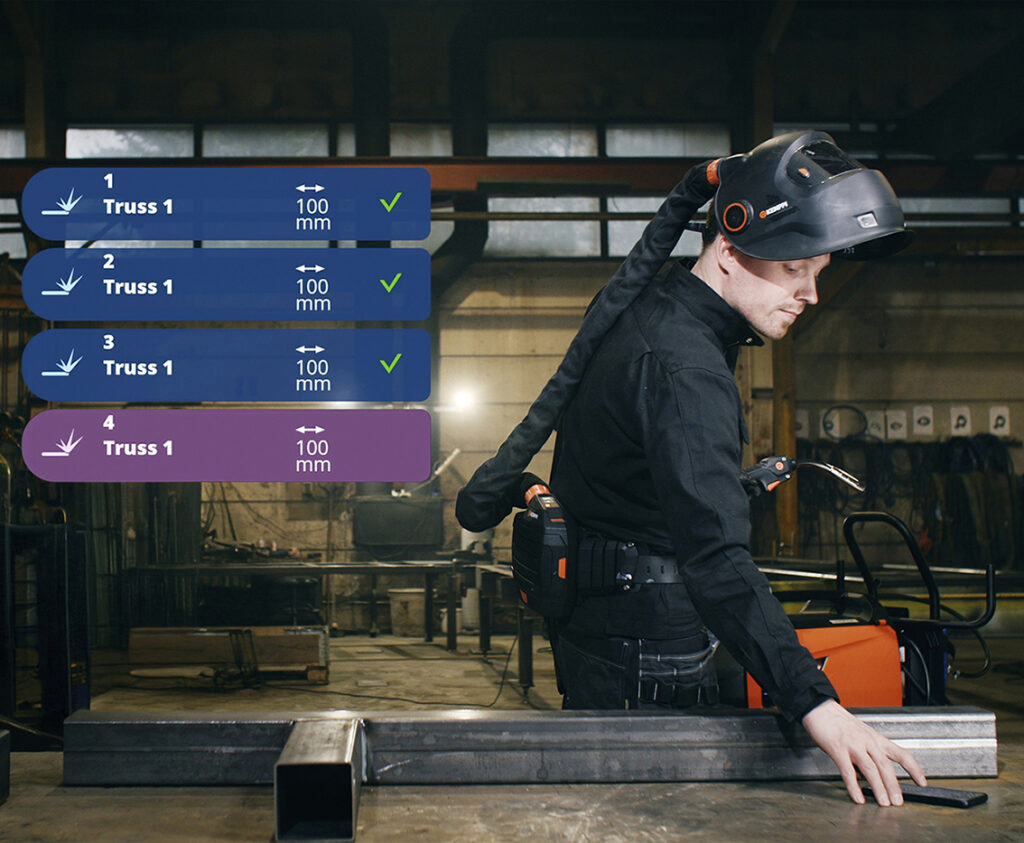

When this equipment is used with our WeldEye welding management software, customers can manage their welding procedures, welder qualifications, and reporting in one place. It also gives them full weld traceability in real-time, when projects require it. For steel fabricators, this means less risk, better weld consistency, and more confidence that quality and compliance are under control without making the job harder for the welder.

Add to this our “Max” and “Wise” Processes, and cobot and robot ready platforms, and you really start to see how we are empowering fabricators and helping extend their capabilities.

Innovation is clearly central to Kemppi’s reputation. How does the company stay at the forefront of welding technology and digitalisation?

Innovation at Kemppi comes from long-term investment in research and development which is largely completed in-house with our own R&D team. Just as importantly, we stay close to customers and incorporate their feedback. We spend a lot of time listening to welders and fabricators, and understanding what exactly causes problems on the workshop floor.

These insights also shape how we approach digitalisation. Digitalisation plays a central role in enabling welding to be treated as a controlled production process, where data actively supports quality, traceability, and continuous improvement, rather than just being collected for its own sake.

In a global landscape with intense competition and rapid technological change, what do you see as Kemppi’s greatest competitive advantages?

Experience is a key component of our competitive edge. With more than 75 years in welding, we understand the process very well and we know where things can go wrong. Our global presence further strengthens our competitive edge by allowing us to take proven solutions from different industries and across regions and apply them locally. Equally as important is trust: customers know the Kemppi brand and rely on it to deliver robust, reliable equipment that performs consistently in tough fabrication and construction environments.

Sustainability is increasingly important in manufacturing. How does Kemppi address environmental and social responsibilities through its products and operations?

Sustainability is embedded in the design process of Kemppi products. From an environmental perspective, Kemppi incorporates energy-efficient inverter technology in machines, reduced heat-input welding processes and long product lifecycles, all of which help lower energy consumption, material waste and overall environmental impact.

On the social side, welder safety and well-being are equally important. This is reflected in the design of ergonomic equipment and intelligent solutions that allow welders to produce high-quality results without unnecessary physical strain. Further, our equipment and protective gear contribute to cleaner and safer working conditions across fabrication environments.

Many companies in industrial sectors talk about customer collaboration. How does Kemppi approach partnerships with its clients, beyond just selling products?

We see our customers as long-term partners. This means working openly with them, sharing technical expertise, and staying closely involved well beyond the initial sale. Training, technical support, and ongoing dialogue are central to this approach. Whether we are helping to improve weld procedures, lift quality consistency, or introduce traceability on specific projects, the goal is always to strengthen the customer’s overall welding capability and long-term performance.

Looking ahead, what are your priorities for Kemppi over the next five to ten years? Are there new technologies, markets, or customer needs you’re particularly excited about?

In Australia and New Zealand, our priority is to support fabricators as they deal with productivity pressures, skills shortages, and tighter quality and compliance requirements. We expect digital welding management, automation, and smarter use of welding data to become increasingly important. These technologies enable businesses to work more efficiently while maintaining confidence in weld quality, traceability and overall process control.

Anything else?

Welding plays a critical role in Australia’s steel and construction industries, and supporting welders with reliable equipment, clear procedures, and better process control makes a real difference. At Kemppi, our aim is to make welding safer, more consistent and easier to manage, so fabricators can deliver quality outcomes with confidence.