The St Marys Integrated Project Office (IPO) was named the ASI’s 2025 Sustainability Awards winner for Large Projects—and with good reason. Built as a temporary 200-workstation design and operations hub for Sydney Metro’s six new stations linking St Marys to the future Western Sydney Aerotropolis, the AUD $16 million facility proves that “temporary” can still mean low-carbon, high-quality and built to last.

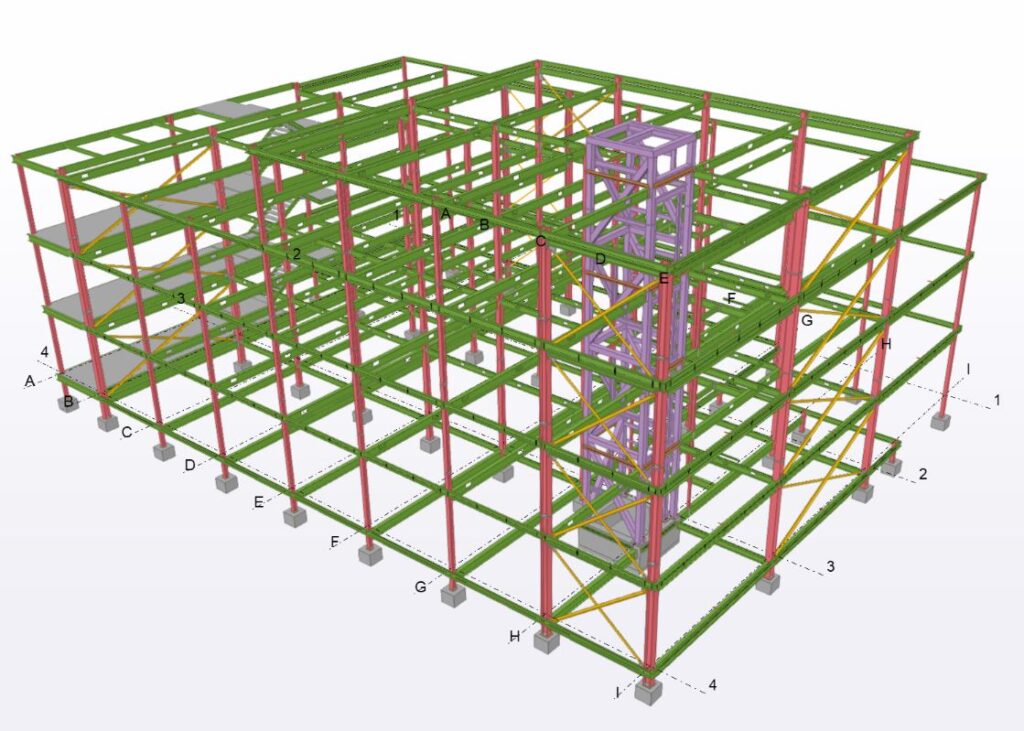

A hybrid structure engineered for reuse

Delivered by Robert Bird Group (RBG) with Built, the IPO pairs a bolted steel frame with cross-laminated timber (CLT) floor panels. The four-level commercial building features a glazed curtain wall, internal stairs, a lift and an outdoor terrace. Crucially, every element—beams, columns, CLT panels and bolted connections—was standardised to enable full disassembly and reassembly. The brief targeted a 50-year design life with planned relocation roughly every 10 years, turning a site office into an asset that can serve multiple metro projects.

Speed, safety and material efficiency

The superstructure—steel and CLT—went up in just 25 working days. A full-height lift core, fabricated as a structural steel truss mast, was erected and installed in four hours, acting as the structural spine during erection, in-service use and future dismantling. Early coordination aligned building grids to standard steel stock lengths, saving about 10 tonnes of steel—an 11% reduction compared to the original grid—and streamlining fabrication and traceability. CLT panels were fire-engineered to avoid passive fire protection, cutting materials and program time. Prefabrication and uniformly bolted connections minimised temporary works and reduced onsite risk.

Measured carbon and a multi-life dividend

This approach not only reduced material wastage but also exemplified how temporary structures can be designed with long-term sustainability in mind for relocation and reuse. The cradle-to-gate carbon (Modules A1-A3) of the superstructure was measured to be 563 TCO2-e. Assuming five lifecycles for the building, this design saved 2,252 TCO2-e on the cradle-togate carbon compared to a series of standard single-use temporary like-for-like structures using prime materials. Material optimisation alone delivered a 33.5 tCO2-e reduction in steel emissions. Digital modelling in Autodesk Revit underpinned precise quantity take-offs and carbon accounting, verified through RBG’s internal quality assurance procedures.

Governance, provenance and responsible supply

Proline Steel, the structural steel fabricator, held Steel Sustainability Australia (SSA) Certification L1, and provided stock lengths that informed the redesign for minimal waste. All procurement and testing quality assurance documentation was reviewed to confirm sustainable sourcing from Australian mills, alignment with project specifications and compliance with relevant Australian Standards and the Building Code of Australia. XLAM supplied PEFC-certified CLT, ‘Declare Red List Free’, with full chain-of-custody, supporting a clean material palette that suits future disassembly, reuse and recycling.

Better places for people, not just projects

Beyond its numbers, the IPO lifts workplace quality compared with typical demountables: abundant daylight through glazed façades, robust insulation and climate control, and generous collaborative spaces. Accessibility is built-in via lift and internal stairs, while the terrace and meeting zones foster team cohesion.

A replicable model for emerging precincts

Believed to be the first fully demountable, relocatable building of its kind for major project offices, the IPO sets a new benchmark for circular, steel-led delivery. With anticipated reuse on future sites such as Bradfield City Centre, it demonstrates how a hybrid steel-CLT system—standardised, bolted and digitised—can cut carbon, accelerate programmes and improve onsite amenity. In short: design once, reuse many times, and keep the benefits compounding.

PROJECT TEAM

- Client: Sydney Metro

- Contractor: Built

- Structural Engineer: Robert Bird Group (RBG)

- Architect: Place Studio

- CLT Supplier: XLAM

- CLT Installer: Savcon

- Steel Fabricator: Proline Steel