Orrcon Steel Manufacturing helps build Australia’s solar infrastructure

In an industrial landscape shaped by the need for cost-effective clean energy, one name is quietly changing the game: Orrcon Steel Manufacturing. With deep roots in Australian manufacturing and a vision sharpened by the realities of energy transition, Orrcon Steel Manufacturing is not only embracing the renewables revolution; it’s helping to drive it.

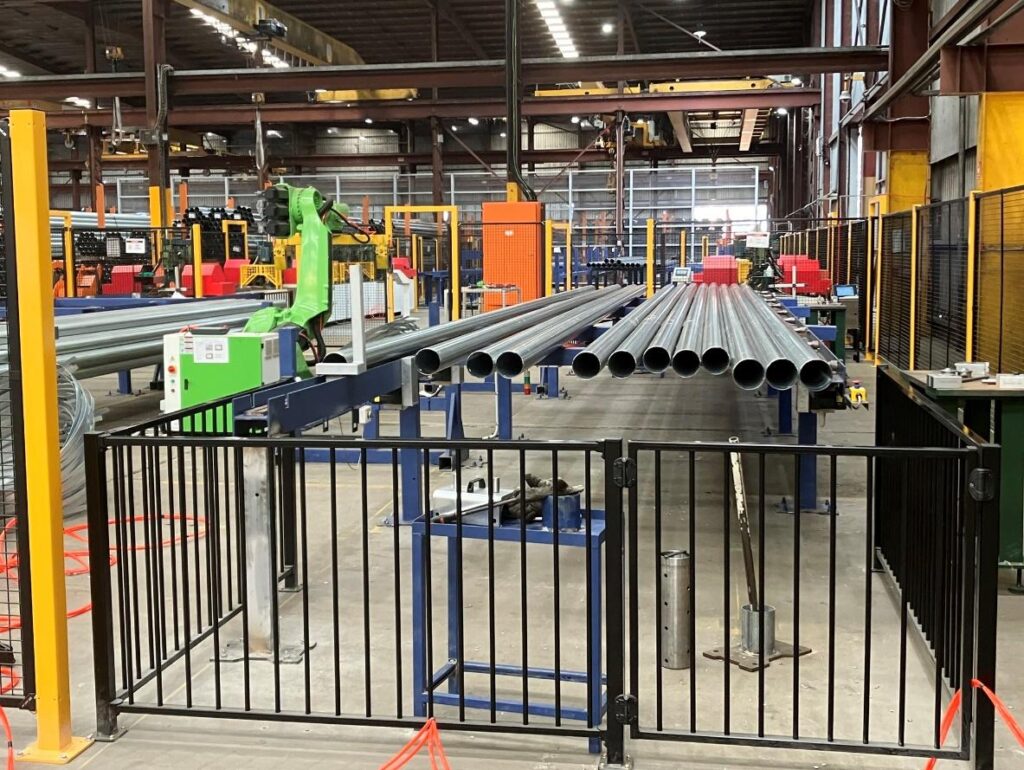

At the heart of Orrcon Steel Manufacturing’s transformation is a strategic commitment to sovereign capability — a concept that has never been more important as Australia seeks to build a resilient, self-reliant renewable energy supply chain. The recent commissioning of the state-of-the-art pipe and tube mill at Unanderra, in the Illawarra region of New South Wales, is proof of Orrcon Steel Manufacturing’s long-term commitment to the nation’s future.

Investing big on sovereign capability

The $70 million investment in the Unanderra mill was not a reaction to market demand but a strategic move years in the making and one supported by parent company BlueScope. Orrcon Steel Manufacturing had the foresight to anticipate the growth of the renewables sector.

“Strategically, we decided to invest in tooling so that when international players approached us, we could say we were ready,” said Tony Schreiber, general manager Orrcon Steel Manufacturing. “That was a bold decision at the time along with the major investment in the Unanderra large tubular mill. Still, it’s how we position ourselves — ready with local content and products when they’re needed, not saying we need two years to tool up.”

The investment wasn’t limited to NSW. Orrcon Steel Manufacturing also bolstered its capacity at its O’Sullivan Beach facility in Adelaide providing expanded capabilities across its three manufacturing sites to provide flexible production that meets the needs of the renewables sector.

It’s a bold strategy, with a further $2 million invested in tooling, by Schreiber’s own estimate. But one that will pay returns, as Australia’s commitment to the clean energy transition gathers pace and more large-scale solar farms commence construction.

Working in partnership with Orrcon Steel Distribution: local capability on display

Orrcon Steel Manufacturing ’s strategic foresight has more recently come into sharp focus through working in partnership with Orrcon Distribution.

The structural tube produced at Orrcon Steel Manufacturing’s Salisbury site in Brisbane from Australian BlueScope steel coil, is then finished at the Orrcon Distribution’s Northgate facility by Baojia, one of Nextracker’s global manufacturing partners. From there, the wholly Australian made components are trucked to sites like Aldoga, demonstrating a fully capable Australian supply chain that supports local jobs and industry capability.

“This collaboration with Orrcon Steel Distribution, Baojia and Nextracker is another example of how we’re making a difference in the utility-scale solar industry with an Australian-made, high-quality product,” said Schreiber.

The numbers are impressive: there is potential capability to supply up to 50,000 tonnes of torque tubes to support more than 2.5 gigawatts of solar energy generation — enough to power hundreds of thousands of homes.

Jobs have been created at Orrcon Steel Manufacturing’s Salisbury site, with plans to add more resources over the next 12 to 24 months as the volumes grow.

Nextracker’s general manager for Australia, Southeast Asia, and New Zealand, Peter Whealer, sees the collaboration as a win-win. “We are reducing our carbon footprint by manufacturing solar torque tubes in Australia. This will give us the added advantage of accelerating the delivery of our utility-scale solar projects and making clean energy more affordable and accessible.”

Building for the future

While demonstrating this capability to deliver an end-to-end Australian manufactured solar torque tube component is a significant milestone, it’s one part of a larger ambition. Through Orrcon Steel Manufacturing’s approach to partner with customers, solar industry OEM’s and large-scale solar farm developers, there is the aim to further build scale and manufacture a range of tubular steel products for Australia’s burgeoning clean energy sector.

But it’s not without its challenges. “We’re committed to local manufacturing, but there’s a real need for government clarity on renewable policy,” said Schreiber. “All we want is a level playing field that helps build and maintain a viable local industry.”

“We’ve invested significantly, with the support of our parent company BlueScope. We just need the right policies that enable domestic manufacturing of torque tube to be competitive and viable”.

It’s this kind of strategic commitment that positions Orrcon Steel Manufacturing as more than just a supplier. They are a partner in the energy transition. With a robust local supply chain, cutting-edge facilities, and a commitment to quality, Orrcon Steel Manufacturing is setting itself up not just for today’s projects but for the next generation of renewable energy development.

Orrcon Steel Manufacturing’s commitment is aligned with broader policy goals. The Queensland Government’s aims is to drive the state toward achievable renewable targets encouraging investment in local manufacturing along the way.

For Orrcon Steel Manufacturing, the future is clear.

“With our parentage through BlueScope, we have the support and strength for many years ahead,” said Schreiber. “We’re planning up for the next five to 10 years. The renewables revolution is inevitable. We want to ensure that when it comes, Australia has the capability it needs—here, and ready.”

In a world hungry for clean energy and resilient supply chains, Orrcon Steel Manufacturing is showing what it means to be ready.

Aldoga solar farm

Aldoga solar farm

The first large-scale solar project in Queensland to incorporate Australian-made steel torque tube

The 380MW Acciona Energia Aldoga Solar Farm project is located approximately 20 km north-west of Gladstone on the central Queensland coast. It requires high-quality steel torque tube components that meet the precise standards needed for solar panels to be efficiently installed. This called for a seamless integration of raw materials, advanced manufacturing, and precision engineering.

The solution

Entrusted with manufacturing tube for supply into the Aldoga project, Orrcon Steel Manufacturing leveraged its manufacturing capability and partnerships:

- Sourcing Australian-made materials. The journey began with Australian-mined iron ore, processed into steel coil at BlueScope’s Port Kembla Steelworks.

- Advanced manufacturing. Orrcon Steel Manufacturing, at its Salisbury, Brisbane-based mill, shaped the steel coil into high-quality structural tube; one key raw material for solar farm components.

- Post processing. Then at Orrcon Steel Distribution’s Northgate facility, through its partnership with Baojia Engineering, these structural tubes underwent further processing which combined to meet the exacting standards to enable accurate solar panel mounting.

- Local delivery. These Australian-made steel tubes are delivered to the Aldoga Solar Farm, where they are mounted onto brackets, ready for the solar panels to be installed by the Acciona Energia team.

- Cutting-edge integration. With an efficient local supply chain, Nextracker seamlessly incorporated the Australian manufactured torque tubes into its advanced tracking systems.

With most large-scale solar farm’s exclusively using imported torque tube and other steel components from Asia, the collaborative approach of the partners in the Aldoga Solar Farm to seek a local supply alternative clearly demonstrates the Australia steel industries willingness and capability to provide locally milled and manufactured steel tubular components for large-scale solar projects.

Completed seven months ahead of schedule in April 2025, Aldoga’s Queensland project is a significant step for Orrcon Steel Manufacturing, showcasing its commitment to the multi-decade journey, as a partner in local manufacturing, sovereign capability and Australia’s renewable energy transition.