A boutique stadium construction has topped half of the categories in the latest Steel Design Awards for Queensland it was revealed on 3 August 2012 at the Brisbane Convention and Exhibition Centre.

The new home of the Gold Coast Suns AFL team won in the Buildings – Large Projects and Engineering – Infrastructure, Resources and Mining categories for its use of lightweight steelwork supporting a membrane canopy and efficient incorporation of standard sized steel sections.

The judges were particularly impressed by the project’s scale model wind tunnel testing of the steel roof structure, expert roof membrane design input, and impact assessment of faceted solar arrays to confirm structural soundness.

The structure also takes advantage of the design flexibility enabled with steelwork via bolted connections to allow the structure to readily adapt for hosting higher profile international events as the need arises.

A strikingly angled 4WD retail and showroom building with a ‘folded’ façade that grabs attention on a busy motor trader strip in Townsville topped the Buildings – Small Projects category. The building’s distinctive angular profile was also designed with the region’s cyclone-prone climate in mind.

The wholesale embrace of weathering steel as a cladding material to suit a naturalistic setting attracted the win in the Steel Clad Structures category for the Fitzgibbon Community Centre in Brisbane. Awards convenor, ASI State Manager – QLD, John Gardner said the winning projects embodied the design flexibility, environmentally sustainable responsibility and structural integrity achievable with modern steelwork.

Buildings – Large Projects

- Metricon Stadium, (Winner)

- River Quay, South Bank (Highly Commended)

Buildings – Small Projects: Opposite Lock 4WD Retail and Showroom (Winner)

Steel Clad Structures: Fitzgibbon Community Centre (Winner)

Engineering Projects: Metricon Stadium (Winner)

Undergraduate Engineering Student Awards

- Patrick Fletcher (The University of Queensland)

- Mitchell Lees (Central Queensland University)

- Mitchell Mulvey (Griffith University)

- Jarryd Londino (James Cook University)

- Scott Smith (University of Southern Queensland)

- Dylan Williams (Queensland University of Technology)

Buildings – Large Projects: Metricon Stadium, Carrara (Winner)

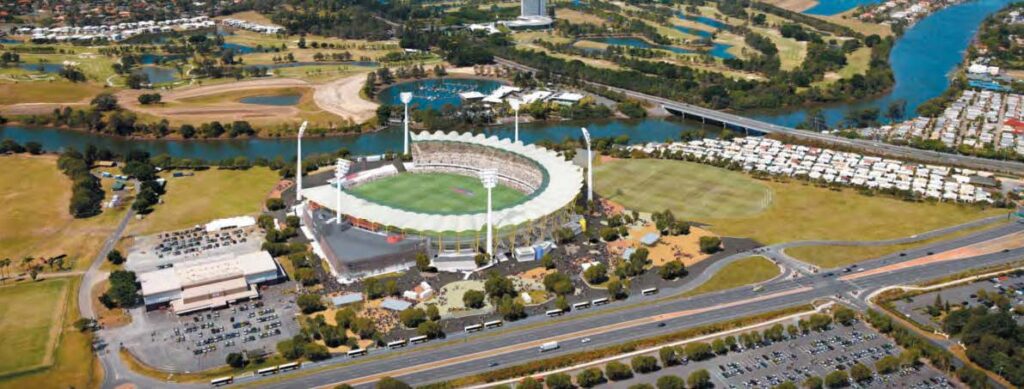

This 25,000-seat facility is new home for the Gold Coast Suns AFL team and the proposed main stadium for the 2018 Commonwealth Games. The project team met a reasonably tight budget and fast tracked construction program with a precast and steel stadia incorporating a lightweight curved form membrane roof supported via curved CHS members, in turn supported via simple planar CHS trusses on a large 12-14m grid, the structure achieving benchmark steel weights for a roof of this kind of around 40kg/sqm. The stadium bowl and Western Grandstand are entirely steel framed from top of pile cap to tip of roof for constructability and to speed erection. Standard UB, WB, UC, WC and CHS sizes were used throughout for swifter fabrication and site delivery.

PROJECT TEAM

- Architect: Populous

- Structural Engineer: Arup

- Head Building Contractor: Watpac

- Steel Fabricator: Beenleigh Steel Fabrications

- Steel Detailer:TD Drafting Services

- Steel Processing: BSF Metal Centre

- Profile Cutting: Pipe Profiling Services

- Hot Induction Bending (CHS): Inductabend

- Coatings Contractor: Tranzblast Coating Services

- Coatings Suppliers: International Protective Coatings, Industrial Galvanizers

- Steel Distributors: BlueScope Distribution, OneSteel

- ASI Steel Manufacturers: BlueScope Steel, OneSteel

Buildings – Small Projects: Opposite Lock 4WD Retail and Showroom (Winner)

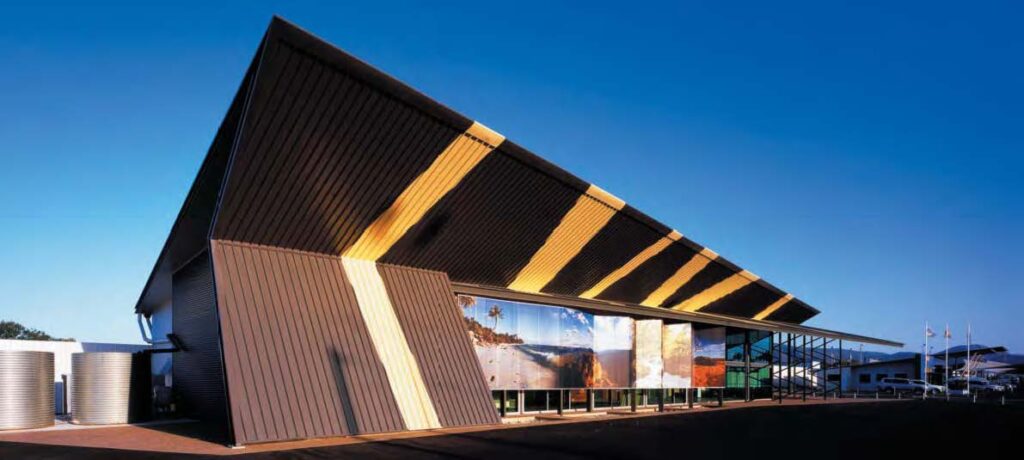

Steel was the apt choice allowing for off-site prefabrication and slender spans of this distinctive angular structure on a busy motor trader strip in Townsville. The profile of the sheeting and selection of a wide tray also provide the durability and strength required for the rugged north Queensland climate, particularly evident in recent cyclones there. To achieve the angular aesthetic of the building, prefabrication of the steelwork off-site reduced the time required onsite to set out the geometry of the building and also provided the tolerances required. The use of 3D CAD technology to set out the form both in the initial design stages of the project and by the steel fabricators facilitated effective communication of design intentions at the construction stage of the project.

PROJECT TEAM

- Architect: Guymer Bailey Architects

- Structural Engineer: Northern Consulting Engineers

- Head Building Contractor: B & T Constructions

- Metal Building Contractor: Colin Braszell Roofing

- Steel Fabricator:Thomas Steel Fabrication

- Steel Detailer:Thomas Steel Fabrication

- Coatings Contractor: Waters Abrasive Blasting

- Coatings Supplier: Jotun

- Steel Distributors: BlueScope Lysaght, BlueScope Distribution, The Steel Barn

- ASI Steel Manufacturers: BlueScope Steel, Orrcon Steel

Engineering – Infrastructure, Resources and Mining: Metricon Stadium, Carrara (Winner)

The venue was designed to accommodate an additional 15,000 patrons for the Commonwealth Games with the lower bowl of precast terraces designed on the northern end to be removable for extending the pitch. A three-coat polysiloxane paint was applied to enhance long-term performance of the steelwork and steel installed below ground or where inaccessible to maintenance was hot-dip galvanized. The stadium was designed to be primarily shop fabricated and bolted together to minimise material use and waste and enhance construction speed. Both Arup and Populous collaborated at all times during documentation and TD Drafting used their 3D model to readily interrogate the structural details enabling quicker resolution of the details.

PROJECT TEAM

- Architect: Richard Kirk Architect

- Structural Engineer: Cardno

- Head Building Contractor: Grindley Construction

- Metal Building Contractor: Grindley Construction

- Steel Fabricators: Lowline (cladding) /Kyst Engineering (structure)

- Steel Detailers: Lowline (cladding) /Kyst Engineering (structure)

- Coatings Supplier: International Protective Coatings

- Steel Distributors: BlueScope Distribution, OneSteel

- ASI Steel Manufacturer: BlueScope Steel (cladding)

Steel Clad Structures: Fitzgibbon Community Centre (Winner)

The building is fringed by sculptural blades of weathering steel as a material visually reminiscent of the corroded car bodies once found onsite. The blades form a rippled screen to the street which reveals glimpses through the building, behind which the building is clad in stained plywood with ample operable glazing to allow natural ventilation and large overhangs to provide natural lighting. All elements of the building were rationalised from the building’s structural systems, framing and cladding that provided for ease of construction, economy of materials and limited wastage. The architect’s 3D CAD model was utilised to generate all levels of information from photo-realistic visualisations, production of working drawings and review of shop drawings. This level of accuracy was particularly important in coordinating precise detailing with fabricators and detailers.