Galvanized coatings on steel, which are part of the metallic coatings range, are typically known to be a long-term, durable and cost-effective means of protecting steel from the effects of corrosion. This usually requires zinc to be applied to the steel during the galvanizing process.

The zinc provides protection to the steel by sacrificing itself in corrosive environments instead of the steel.There are several ways of applying the zinc coating with each process having its own unique characteristics and performance. These include hot dip galvanizing (HDG), sherardizing, electroplating or electrogalvanizing and zinc (thermal) spraying. Of these, the HDG process is quite robust and the most popular.

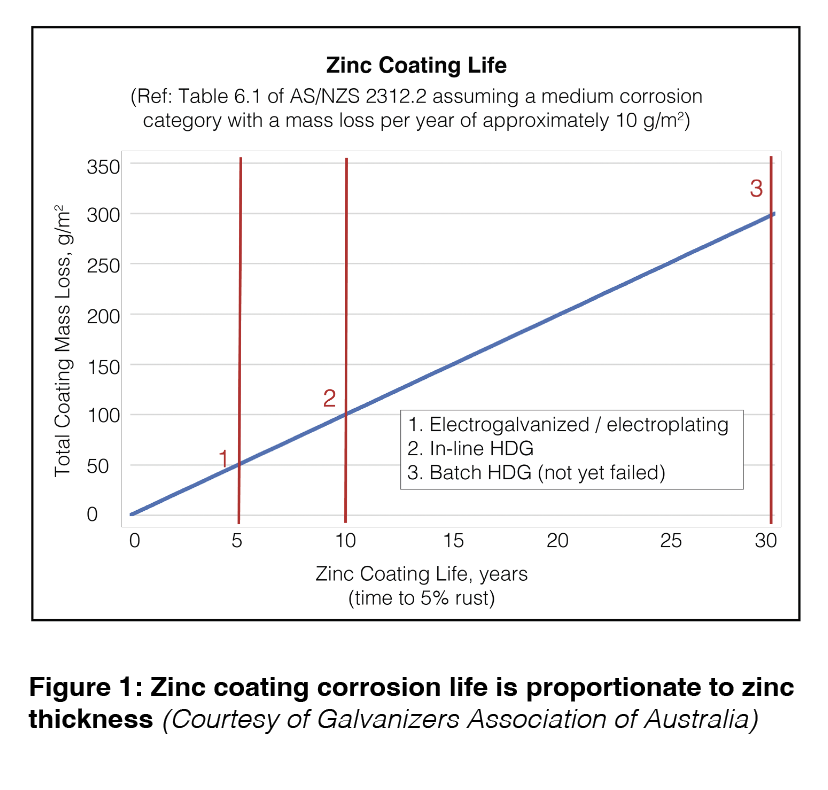

It is well known and scientifically established that for metallic coatings the zinc thickness is proportional to service life (ie durability or life to first maintenance in a corrosive environment). Specifically, double the thickness and the service life is doubled in corrosive environments. This is particularly noted in key Australian Standards such as AS/NZS 2312.2 Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings, Part 2: Hot dip galvanizing and attested to by Figure 1.

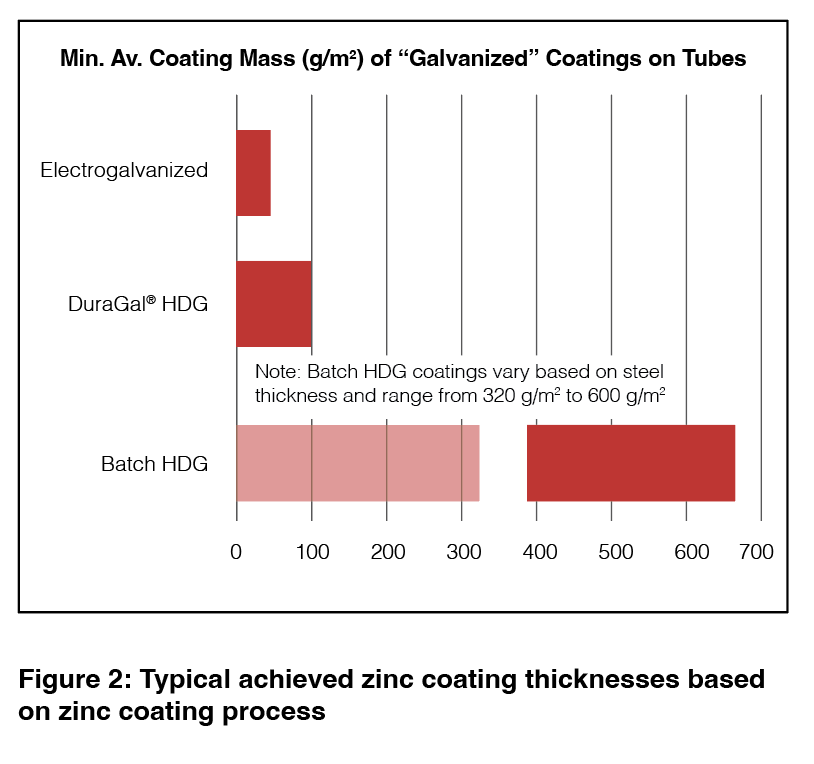

Figure 2 shows the relative thickness from the various metallic (zinc) coating types. As evidenced in Figure 2, there are many metallic coatings that could be considered to be HDG. In-line HDG galvanized (such as DuraGal®) and electrogalvanized tubular products are popular, as they serve a niche in the metallic coatings market for structural applications.

Their benefits from a lower coating thickness include:

- Easier manipulation and bendability without coating failure (such as flaking and so on)

- Easier weldability

- Whilst still satisfying adequate service lives in corrosion environments as described in AS/NZS 2312.2

Consequently, we shall focus on the last two types of galvanizing as noted in Figure 2. In subsequent parts to this commentary, we will explore additional facets of HDG compared to other relevant metallic coatings.

The fundamental basis of hot dip galvanizing (HDG) is the zinc coating is applied by the immersion of the steel in a molten zinc bath. This allows for a metallurgical bond to be formed between the steel substrate and the zinc such that when you analyse the cross-section of the steel and coating, it varies from free zinc to steel with intermediate layers of zinc-steel phases.

In essence it is said that the ‘steel and the zinc become one’. Such a trait ensures a good adhesion and abrasion resistance of the zinc to steel as exhibited by the well-known Batch HDG and related In-line HDG galvanizing processes.

Processes such as thermal spray, zinc rich paint, and electrogalvanizing do not exhibit this trait. Though utilising heat, the application of zinc in the thermal spray and similar processes are different to that of batch or in-line HDG galvanizing processes. Electrogalvanizing does not have any significant heating requirements and relies on electro-static attraction of zinc to the steel in a cold chemical solution of zinc and can only economically provide thinner zinc coatings.

Essentially, electrogalvanizing (also known as zinc or electroplating) is a process where zinc is applied by using an electrical current. While it does provide some corrosion protection, its thinner coating is not as rust resistant as hot dip galvanizing. A problem arises where there is the market perception that the standard available electrogalvanized coating is the same as in-line HDG coatings. They really are not.

Austube Mills manufactures its DuraGal® range of structural pipe and tube products with in-line HDG coating which has unique benefits.For numerous reasons, not all gal is DuraGal®.

This article is part of a paid advertising package.