2024 ASI Steel Excellence Awards: National Winner - Steel-Clad Structures

The Melbourne Quarter precinct is among one of the largest mixed-use urban regeneration developments to occur in the city. Sited across from the Southern Cross Station, the objective behind the precinct is to activate and connect a previously underutilised gap between the CBD grid and Docklands. The Melbourne Quarter Tower, at 426 feet tall, is the largest of three office and residential towers in the precinct, reaching 35 levels.

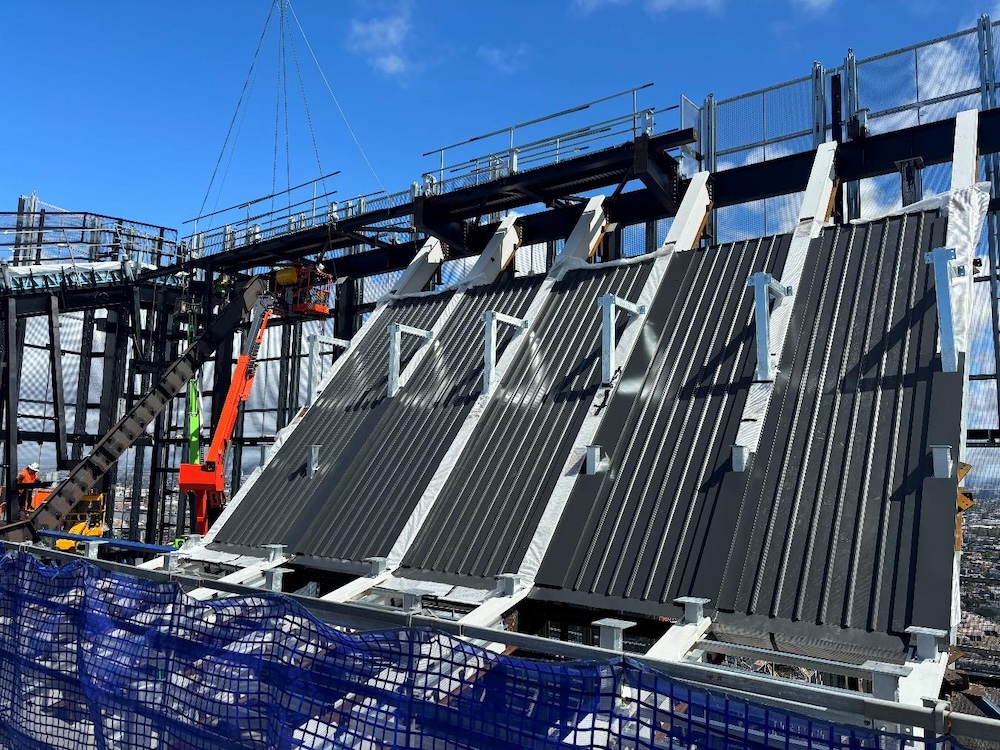

It features a unique roof design that enables maximum floor volume in line with council requirements. The roof consists of 700t structural steel framing from Level 28 to the plantroom area on Level 35. Given the 28-degree pitch roof, the steel framing was designed to enable a large portion of the steel, roofing, skylight framing and services to be constructed off-site and lifted into place safely and efficiently.

The roof was separated into two stages: the modular roof section encompassing 53 modular cladded frames, five x 20t central spine frames, locally fabricated box section columns (up to 1.2m deep x 16m tall) and locally procured WB primary beams; and the hull plantroom framing which included 10 modular cladded frames, BMU garage, cooling tower platforms and pergola framing.

The hull plantroom required extensive coordination with several trades. By staging the elements into 16 areas, ArcStructural was able to develop a safe, efficient strategy with Lendlease and all contractors. The wall framing was temporarily engineered with propping to support screens being fixed to the structural steel. Given the columns were 13.5m high and in some instances 16m high the screens could not be supported by the slabs. The upper roof framing was modularised with roof cladding, roof access safety systems and temporary handrails.

Some hockey sticks were set-up in ArchStructrual’s off-site cladding facility so that all fire board, roofing and Speedpanel could be installed prior to erection. The BMU garage was assembled in two primary frames weighing 15t each. This garage housed a 40t BMU which tracked down the central spine frames on a winch system along large CHS rails Cooling tower platforms were assembled in six modules off-site. Access was extremely difficult with these areas situated above a 40-degree fully clad roof and services skids. Pergola frames also had to be assembled into four frames in the site loading dock. Pergola frames were 8m wide x 12m long when fully assembled. By assembling these on the ground required less access points above services, cooling towers and steel to navigate.

The project comprised over 60 modules and various other assemblies with over 26,000 documented welds—equivalent to over 70km of deposited weld. This included specialised welding sequences and preparations for several connection plates on the spine frames comprised of Z-25 grade plate. This required controlled pre-heat and run sequences to avoid the possibility of lamellar tears in the thick material.

PROJECT TEAM

Entering Organisation: ArcStructural

Architect: Woods Bagot

Structural Engineer: AECOM

Head Contractor: Lendlease

Distributor or Manufacturer: Steelforce

Steel Fabricator: ArcStructural

Steel Detailer: PlaniT Design Group, Delta Structures, Bellarine Steel Detailing, NewSteel

Coatings Supplier: Action Alliance, Geelong Galvanising