The ‘Reimagining Arnolds Creek’ project was a transformative 5km creek line revitalisation in Melton, 50km north-west of Melbourne. The project was designed to create a contemporary space for the local community, and improve both biodiversity and waterway health.

Prior to implementation of the project, local neighborhoods were divided by the existing Arnolds Creek concrete drainage channel—an unsightly, dry and under-utilised parcel of land with little shade or amenity.

The old drainage channel was transformed with vegetation and high-quality landscaping, as well as community amenities like benches and tables. The project included the planting of approximately 200,000 plants and trees, as well as the construction of walking tracks to better connect neighbourhoods to nearby schools, shops and community services.

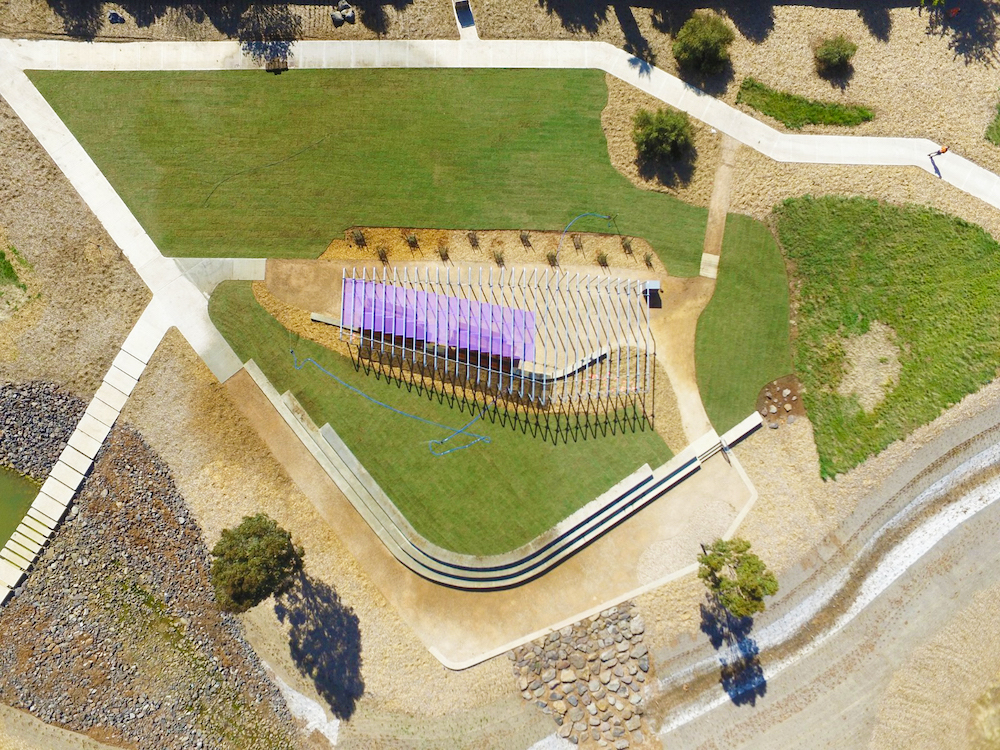

The Arnolds Creek Shade Structure sits at the heart of the project. This custom galvanized steel arbour is a visually striking ‘skeleton’. The structure marks the joining of two local creeks connecting the man-made elements to nature.

Galserv was engaged by park designers Fleetwood Urban (working in conjunction with REALstudios) to construct and deliver the galvanized steel arbour. Galserv hot-dip galvanized approximately 10 tonnes of steel to create the giant skeleton-like structure. The design featured 30 tall, long steel arches spanning a footprint of approximately 25m. Each arch included several components varying slightly in size and bend.

While individually the pieces appear unremarkable, their meticulous design variation across each arch was critical to creating the ‘living form’ for the project.

Use of hot dip galvanizing

The project demanded a long-design life and needed to provide robust resistance to human and environmental wear. Hot dip galvanizing was chosen not only for its visual appearance but its reliability and durability. When compared to paint, it was calculated that hot dip galvanizing would last decades before requiring substantial maintenance.

These factors appealed to project stakeholders in two key ways: the initial construction using hot dip galvanized steel over other materials presented best value; and the overall cost of asset maintenance for the life of the structure was far less than painted finishes.

According to Galserv’s account manager Adam Chessell, “Galvanizing was chosen for the Arnold’s Creek Shade Structure for the high quality durability it provided, at the lowest cost, for the environment in which it is located. As the structure is installed in a public park, easy repair and maintenance in the wake of graffiti or other damage was important. Galvanizing satisfies this criteria.”

Complex in concept and execution

The shade structure was highly complex in concept and execution. The structure was designed and modelled three-dimensionally so that its final form could be considered from multiple perspectives, light levels and environmental conditions to ensure the intended performative qualities were achieved.

Hot-dip galvanizing was a deliberate choice to enhance the connective design with its surroundings and achieve a cohesive blended look. The structure needed to appear like a ‘giant skeleton’ of individual elements

emerging from the earth that appears to change shape when viewed from within, around or at a distance. Yet, in its design it also needed to look identical and whole so that each part was indistinguishable from the next. As a result, the end design included many components that appeared the same, but actually varied slightly in shape and size. It was critical these components, especially those joining to create a continuous arch, came together seamlessly on-site in both construction and appearance.

The meticulous considerations of the design and planning of the structure flowed through to the hot dip galvanizing process. The brief from the client, Fleetwood Urban, was clear: a continuous and seamless finish had to be achieved when the components were assembled. Central to the design of the structure was a series of hollow pipes of various lengths and bends. Steel sections like these present a challenge at the galvanizing kettle. A poorly engineered design can trap pockets of air, preventing a complete coating inside and out.

All these factors required Galserv to work closely with Fleetwood Urban early, and consistently, throughout the project, to ensure all technical, logistical and quality aspects were successful.

“We collaborated closely with Fleetwood Urban—experts in play, access and shade structures—on this project. Fleetwood Urban’s designers are very creative, bringing the vision of the architect into real life. With this creativity, it means that very few of the structures they design include standard pieces and products. All the pieces are custom and varied. There is no standard height, size or design. Without stock standard dimensions of steel, the handling of the pieces during galvanizing becomes more complex, as does achieving consistent quality,” Chessel said.

“To overcome this challenge, we galvanized the pieces individually—rather than in the usual batches—to ensure the best possible quality. While this type of process is more costly and time consuming, it delivers a much better aesthetic.”

“We ensured all the material we received was grit blasted first, before galvanizing, to give it a more consistent finish. We also sandblasted the circular hollow sections before galvanizing. Then as soon as the galvanizing process was complete, we got it offsite as quickly as possible to avoid double handling,” Chessell said.

Market development potential

The shade structure, and the use of hot-dip galvanizing, was a considered and well-designed focal point for design life and appearance. The project set a new standard in the approach to creating green spaces in existing areas with significant community engagement and deep consideration for the environment.

“Fleetwood Urban is looking to replicate this project across Victoria and Australia—the idea is to revitalise dead community spaces so that the local population has a usable, functional space. This project demonstrates that galvanizing is key to ensuring the longevity of these types of structures,” Chessell said.

“This project proves that the package of work doesn’t have to be huge to garner interest in galvanizing, or demonstrate the benefits that galvanizing has to offer. Often, galvanized steel is part of a building or a structure, and it can’t really be seen or appreciated because it’s hidden. The Arnold’s Creek Shade Structure put galvanizing on display in a piece of public artwork.”

“The structure really stands out. It looks like a skeleton—or like the bones of a dinosaur, or the ribcage of a huge whale. At different times of the day, it casts different shadows and plays with the light. Viewed from afar, the structure is more like a piece of art than an arbour. It was a great project to work on alongside Fleetwood Urban.”

Project team

- Clients: Melbourne Water, Melton City Council, Western Water and Department of Environment, Land, Water and Planning

- Hot Dip Galvanizer: Galserv® (NEPEAN™ Building & Infrastructure)

- Shade Structure: Fleetwood Urban

- Architect: REALMstudios

- Project Consultants: Alluvium Consulting and Mosaic Insights

- Environmental Engineering: E2DesignLab